Nonwovens play an outstanding role in the filtration industry today due to their numerous properties and qualities. The reason for this is, as in other applications, the variety of materials, the many manufacturing techniques with their different range of characteristics as well as the almost limitless possibilities of function.

Through targeted functionalisation or refining, nonwovens can be provided with well-targeted properties as required. In the area of filtration, properties such as pore quantity and pore distribution are just two of the important parameters for an effective filtration system.

Primarily, Lantor nonwoven filtration materials cover the following areas of application:

- Drilling emulsions

- Waste washing water

- Grinding emulsions

- Phosphate solutions

- Cutting emulsions

- Water

- Honing emulsions

- Air

- De-greasing emulsions

- Hydraulic oils

- Gas

- Oils / Aerosols

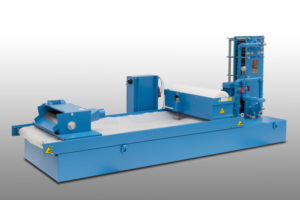

Lantor nonwoven filtration materials are suitable for all commonly used filter circulation systems on the market:

- Gravity belt filters

- Pressure belt filters

- Vacuum belt filters

Central and single plant can be fitted with Lantor nonwoven filtration and thereby achieve a high level of purity at the same time reaching a high level of cost efficiency.

An overview of Lantor nonwoven filters:

- Needlepunched nonwovens for air filtration

- Roll goods for belt filter plant

- Filter sacks for various filtration needs

- Stamped parts

- Roll goods for filter circulatory systems

- Gravity belt filters

- Circulatory belt filters

- Vacuum belt filters

The Lantor nonwoven filter folder can be simply and quickly ordered at the special webpage we have set up under sample order.

CONTACT PERSON

Alina Sandikci

Tel. +49 6021 649-43

sandikci@lantor.de