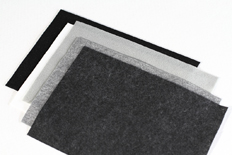

Needle punched nonwovens are formed mechanically by the so-called carding method, which uses machines with rotating cylinders on which staple fibres are laid out as a broad web. Using this method directional orientation is possible and also heavier articles can be produced with several layers. After this follows the needling as well as the bonding and compression of the nonwoven through pricking with barbed needles.

This serves the binder-free manufacture using the most intensive and even interlocking and interlacing of the fibres in a third dimension. For this purpose a fast reciprocating needle bed is moved up and down and the web is drawn through two perforated metal plates in the needling area. Using this needling technique, an almost smooth and stripe-free surface can be achieved as well being structured and patterned.